Safe. Precise.

Proven Lifting Systems

Since 1972.

For over fifty years, Permadur has been an industry leader in lifting technology — providing magnet, vacuum, and load positioning systems trusted across North America and Mexico. Every system we build is engineered for reliability, compliance, and long-term performance in demanding industrial environments. From high-cycle production lines to custom fabrication floors, our electrically controlled permanent magnets and vacuum lifters ensure operators can move material safely, efficiently, and confidently.

About Us

Family-Built Since 1972 — Hillsborough, NJ.

Permadur’s story began with a simple goal — to make lifting safer and more predictable. Over the decades, we’ve grown into one of the most respected names in magnet and vacuum lifting systems, serving industries from steel service centers to shipyards and heavy equipment manufacturers. What makes us different is our unwavering focus on engineering integrity and lifecycle support.

Each system we produce is backed by in-house design, testing, and documentation to meet or exceed ASME standards. Our team of engineers and technicians doesn’t just build lifting solutions — we partner with clients through installation, certification, and long-term maintenance. When you choose Permadur, you’re choosing experience, safety, and craftsmanship that has been refined for more than five decades.

Our Core Business

Lifting Solutions

Across every material-handling environment, the demands are different — but the expectation for safety and uptime is the same. Permadur systems are trusted in steel service centers, structural fabrication shops, shipyards, and manufacturing plants where reliability and operator confidence are critical. Each application we serve is backed by decades of experience and a deep understanding of how different materials and production workflows operate.

From reducing manual touches in metal fabrication to increasing torch “ON” time in burn table operations, Permadur systems help improve throughput and minimize risk. Our technology delivers measurable ROI through fewer setups, safer lifting, and reduced operator fatigue — all supported by engineering documentation that makes audits and inspections straightforward.

Our Products

Engineered Systems for Every Lift.

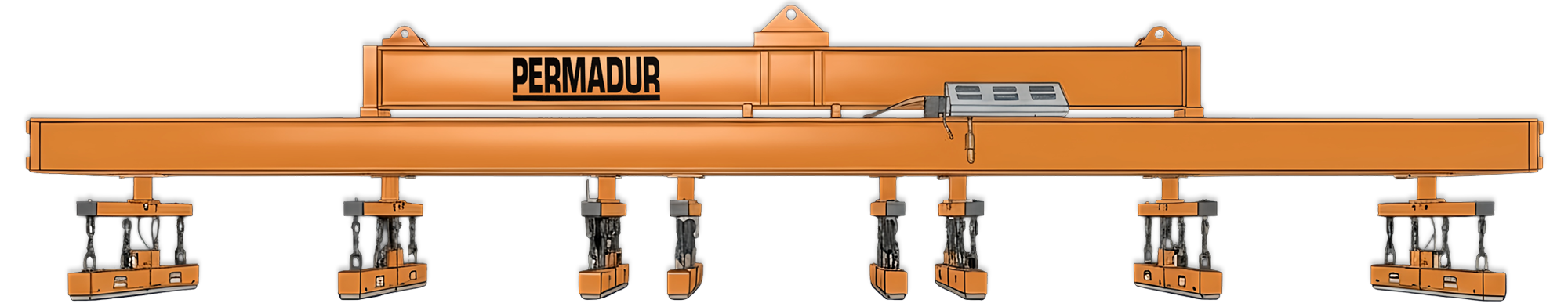

Permadur’s lifting equipment is built to handle everything from thin sheet to massive structural plate. We manufacture electrically controlled permanent magnets (ECP), vacuum lifters, and load positioners designed for repeatable, safe, and efficient operation. Each product family is tailored to specific materials and environments — giving you total control over precision, lifting speed, and compliance documentation.

Our magnets and vacuum systems are field-proven in hundreds of facilities, combining modern control systems, safety interlocks, and indicator lighting for complete operator assurance. Whether you’re performing de-stacking, staging, loading, or precision positioning, Permadur offers a solution configured for your duty cycle, surface condition, and space requirements.

Service & Repair

Your lifting equipment is a safety-critical investment — and maintaining certification is essential to long-term performance. Permadur offers comprehensive maintenance, inspection, and repair services to keep every magnet and vacuum system operating at peak condition. Our team provides on-site or in-house diagnostics, recertifications, and detailed inspection documentation aligned with ASME BTH-1 and B30.20 standards.

Whether you require preventive maintenance, a full magnet rebuild, or replacement of pads, seals, or controllers, we respond quickly with OEM-grade parts and factory-trained expertise. Each repair is verified and documented so your team can operate with confidence. With Permadur Service, you can extend the life of your lifting systems, maintain compliance, and avoid costly downtime.

Lifting Solutions

Across every material-handling environment, the demands are different — but the expectation for safety and uptime is the same. Permadur systems are trusted in steel service centers, structural fabrication shops, shipyards, and manufacturing plants where reliability and operator confidence are critical. Each application we serve is backed by decades of experience and a deep understanding of how different materials and production workflows operate.

From reducing manual touches in metal fabrication to increasing torch “ON” time in burn table operations, Permadur systems help improve throughput and minimize risk. Our technology delivers measurable ROI through fewer setups, safer lifting, and reduced operator fatigue — all supported by engineering documentation that makes audits and inspections straightforward.

Our Products

Engineered Systems for Every Lift.

Permadur’s lifting equipment is built to handle everything from thin sheet to massive structural plate. We manufacture electrically controlled permanent magnets (ECP), vacuum lifters, and load positioners designed for repeatable, safe, and efficient operation. Each product family is tailored to specific materials and environments — giving you total control over precision, lifting speed, and compliance documentation.

Our magnets and vacuum systems are field-proven in hundreds of facilities, combining modern control systems, safety interlocks, and indicator lighting for complete operator assurance. Whether you’re performing de-stacking, staging, loading, or precision positioning, Permadur offers a solution configured for your duty cycle, surface condition, and space requirements.

Service & Repair

Keep Your Systems Certified and Reliable.

Your lifting equipment is a safety-critical investment — and maintaining certification is essential to long-term performance. Permadur offers comprehensive maintenance, inspection, and repair services to keep every magnet and vacuum system operating at peak condition. Our team provides on-site or in-house diagnostics, recertifications, and detailed inspection documentation aligned with ASME BTH-1 and B30.20 standards.

Whether it’s preventive maintenance, a complete magnet rebuild, or replacement pads, seals, or controllers, we respond quickly with OEM-grade parts and factory-trained expertise. Each repair is verified and documented so your team can operate with confidence. With Permadur Service, you can extend the life of your lifting systems, maintain compliance, and avoid costly downtime.

Resource Center

Downloads, Standards, and Expert Guides.

Knowledge is key to safe, effective lifting. The Permadur Resource Center brings together all of our documentation, CAD files, operation manuals, safety guides, and selection tools in one accessible location. Engineers can quickly reference detailed specifications, wiring diagrams, and ASME compliance information to ensure installations meet internal and external standards.

You’ll also find expert guides explaining how to choose between magnet and vacuum systems based on material type, thickness, and surface conditions, along with videos demonstrating real-world applications. Whether you’re designing a new system or maintaining an existing one, this library gives you the tools and confidence to make informed decisions every step of the way.

The Latest from our Blog

Can Permanent Lifting Magnets Be Used on Stainless Steel or Aluminum, and When Should You Choose a Vacuum Lifting System Instead?

Why this question matters If you’ve ever watched a shiny stainless-steel plate slip out of your...

What Are the Advantages and Limitations of Vacuum Lift Systems for Delicate or Non-Magnetic Materials?

Choosing the Right Tool for Fragile Loads Imagine trying to move a large sheet of polished...

How Often Should Permanent Lifting Magnets Be Inspected and What Safety Checks Are Required?

Why Regular Magnet Inspections Are Critical When you’re responsible for moving heavy steel plates,...