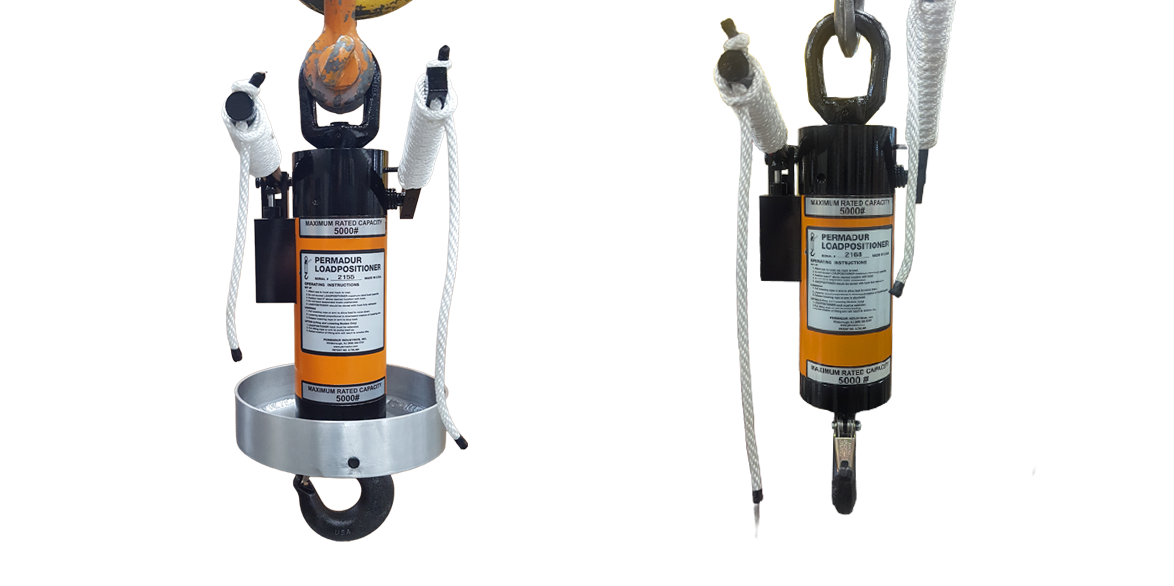

Permadur Load Positioners

Precision Lifting & Lowering

Product Description

Overview

Permadur Load Positioners provide precise, repeatable control for lifting and lowering while protecting tooling and equipment. Acting as a hydraulic link between the hoist and the load, they enable positioning within thousandths of an inch. The Model L is designed for lifting only, while the Model LL offers both lifting and lowering capability. Available in capacities up to 40,000 lbs. with 3” to 12” stroke options, Permadur Load Positioners simplify alignment and reduce downtime.

Key Benefits

- Reduces machine and tooling damage

- Improves alignment, assembly speed, and quality

- Available in lift/lower and lower-only options

- Maintains ≤0.001” positioning accuracy

- 5 to 1 safety factor

- Requires no external power

Models

- L Series Load Positioner— lifting only model

- LL Series Load Positioner— lifting & lowering model

- Available in 3” to 12” Stroke Lengths

- Available in 1,000 lb. to 40,000 lb. Capacities

- Load Hook Automatically Resets

- Eliminates Hoist Jogging

Use Cases

Ideal for Airline/Aerospace industry, tool-and-die handling, precision assemblies, placement and operations requiring safe, accurate positioning.

Media

Click to view full-size images.

Problem / Cause / solution / benefit

Problem

In many industrial, manufacturing, and assembly facilities, aligning heavy machinery, tooling, dies, or large components with precision can be slow, difficult, and error-prone. Manual lifting and positioning — or crude hoists — often lead to misalignment, tooling damage, excessive adjustment time, and poor quality control. This can throttle production throughput, increase scrap rates, and drive up downtime during assembly or maintenance.

Cause

Because heavy loads often exceed safe or practical manual handling weight limits, operations rely on crude hoisting or manual repositioning. Traditional hoists may allow the load to be lifted, but they rarely provide the fine control needed to align tooling or components within tight tolerances. Without precise positioning equipment, operators must make multiple adjustments — risking tool or part damage, mis-fits, and operator fatigue — and this iterative re-alignment eats time and reduces production efficiency.

Solution

Permadur Load Positioners provide a hydraulic link between hoist and load, enabling operators to lift, lower, and precisely position heavy loads with repeatable control and within thousandths of an inch. These positioners offer up to 40,000 lb capacity, with stroke options from 3” to 12”, and versions available for lift-only or lift & lower functions. Because they maintain positioning accuracy (≤ 0.001”), they dramatically reduce the need for manual adjustments, eliminate guesswork during alignment, and lower the risk of damaging tooling or equipment.

Benefit

Using Permadur Load Positioners results in faster, safer, and more accurate assembly, alignment, and maintenance operations. Production throughput improves because components and tooling align correctly on the first try — reducing rework, scrap, and downtime. Equipment and tooling last longer due to fewer impacts or mis-alignments. Operational safety rises as heavy loads are handled with precision hydraulics instead of manual force, reducing strain on workers. Overall, businesses save time and money — with higher quality output, lower maintenance costs, and improved reliability across workflows.